THINKING OUT LOUD. UP HOUSE'The future is not what it used to be' - Paul Valery |

Campsite, canvas, network node, connection machine, boundary condition, filter, power station, net sum producer, extended organism, performance space, hotrod, physical prosthesis, play pen, social generator, magazine [makhzan]: memory storehouse, identity engine; - The problem for us as designers and architects is not so much the design of the house but the question as to what kind of society do we wish to live in? Can we make certain desires easier to accomplish? At the very least shouldn't we celebrate those activities we see as most precious and rich? |

|

Up House - a scenario for exploration. |

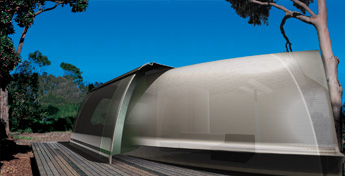

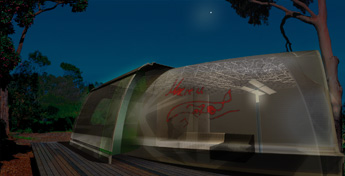

She had decided on a Honda, from reading the Saturday newspaper advertisements in the real-estate section. She liked the taught curves of the main volumes and the extensive features offered with the roll in bathroom module. She had decided to buy the main shell but lease the core service modules. Upgrading was automatic and she could not be sure how her demands on the house might change so reconfiguring these easily was a priority. The structural components were all stainless steel space-frame or tensegrity modules. They are always reusable and a good investment. She was assured that should she even wish to move to a new city high-rise site they would only have to go through a routine structural diagnostic before being re-knitted into a modular frame hanging off a high rise down-town tower. On this site should she wish to later extend or reconfigure its only a matter of some unbolting, some additional 'Techno-Post' screw-in footings, space-frame and appropriate body panels. |

|

The house construction had begun on Monday with the setting out and installation of the screw-in footings. These had required no site clearing or vegetation damage. This immediate landscape was essential to her enjoyment of the location so any damage or clearing to accommodate clumsy or unwieldy construction equipment was out. The footings were screwed in using a compact auger. A small trench had been dug to accommodate the power cable, water and sewage hoses onto the site to connect the house to the grid. The power connection was mainly as an income generator, as with the house's integrated solar array covering most of the building skin and her sporadic occupancy she would be sending most of the power generated back to the grid. Power-station-holiday-homes are quite reasonable low-tax income generators. The sewage connection hose is flexible with a 50mm diameter and is part of a pump-assisted system. All fittings and connections are drip free 'dry break' valve fittings originally developed to handle toxic fluids in the chemical and petrochemical industries. |

Today the two tautliners are scheduled to deliver the house, shell and service systems. Estimated assembly time by 4 installers: 8 hours. The space-frame structure, made up of 20mm diameter stainless tubing, has been factory pre-assembled into 2.4 metre square sections, light enough for two men to carry them onto site. The three way grid with it's triangular pattern can accommodate both rectilinear and curvilinear plan forms. The space-frame platforms form the main deck and the roof trusses. Tensegrity masts and struts finish the chassis of the house, ready for connection of the wall and roofing panels. |

Once the deck is in place it is threaded with a flexible integrated service loom containing all service conduits, plumbing and cabling. The loom is securely clipped to the space-frame and all the currently required service terminals [including dry break connection points for water and sewage], set along the length of the loom in the correct locations in the factory, are positioned in plates to terminate at floor level. The deck is skinned in a matrix of 2.4 metre square composite panels, ranging in finishes from wood to rubber and a metalised recycled plastic depending on the activity zone and weather exposure at that point. The external deck skin carries an embedded circuit of air-ducts used as part of the thermal energy storage collection system. |

page: 1 | 2 | 3 |

2008 © Crowd