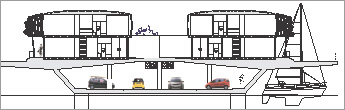

Cloud HousecontinuedStructure |

|

Heat pump and arterial heat circuit |

It is mounted onto a shock absorbing base and is located directly over self sealing quick couple connection points. These supply natural gas into the pod, electricity out of the pod and hot or cold air to and from the thermal storage system as required. The service pod has its own active noise suppression sound system. This can be used to radiate quiet through out the house. |

The floors and roof act as a ducted heating and cooling system like a 'printed circuit' for moving heat and cold air. Ducts are cut into composite floor and roofing material. The air-duct circuit is specifically designed for the demands of a particular building and cutting is a computerised operation, done during manufacture. Heat energy collected from the roof is stored chemically within the 4 central hollow columns and reradiated through the floors as required. The system is reversed for cooling in summer. Movable internal walls are coated with exothermic paint to create large and efficient space heaters in winter. |

Dry break mechanical coupling system for domestic services |

Mechanical vapour recompression bathroom module |

The mechanical vapour recompression unit recycles and distils grey water though an evacuated boiler. This system, pioneered in the dairy industry significantly reduces the energy need to distil water. Distilled potable water is stored in a 200 litre holding tank for reuse in the shower and hand basin and for flushing the toilet. The estimated energy requirement for the system is 1 kilowatt for every 20 litres of purified water. |

The toilet is a dry toilet, using only a tenth of the water required by traditional fittings. The unit features a non mechanical system to liquefy solid waste for efficient disposal. Sewage plumbing cross sections can also be greatly reduced. The toilet pan and shower head retract into the bathroom module and the bath folds up into the shower recess. To compensate psychologically for the reduced water use, lighting is used to emphasise the presence of water, shining through the translucent fittings creating ripple pattens on ceilings and floors. |

CreditsDesign: Michael Trudgeon, Anthony Kitchener |

page: 1 | 2 |

2008 © Crowd